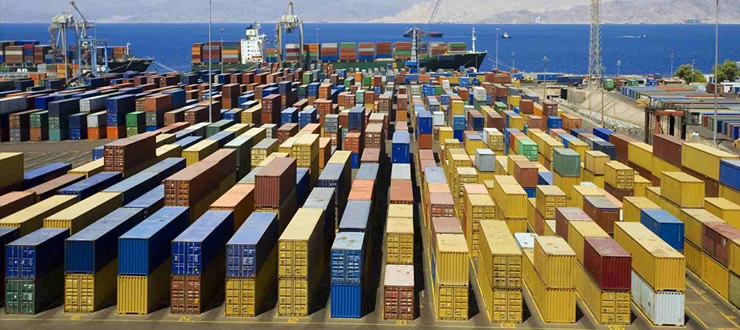

Electricity supplier refinement operation, inseparable from a planned, efficient logistics management system. So, how to achieve a standardized warehouse? Standard shipping how to develop? Treasury planning how to do? Warehouse performance to what standards? How can effective logistics performance?

General business from Slotting Optimization, multi-level inventory, standardized operating procedures, warehousing and other aspects of information technology to improve the operating efficiency of the warehouse.

1 Slotting Optimization, improve operational efficiency sorting

The goods according to their classification, to be orderly arrangement, in plain words, symbols or numbers in place of the name of the goods, type and other information. Scientific coding goods, the goods in favor of accurate coding can be quickly out of storage operations, improve operational efficiency.

In order for warehouse management, orderly and conducive to work out of storage practices, tally clerk should be in accordance with storage requirements and characteristics of the storage space is divided into several regions, the formation of cargo space, and number one is easy to distinguish cargo space, the second is for the sub picking operations to provide a convenient, efficient sorting operations.

2, multi-level inventory, improve inventory accuracy and efficiency of operations

Participating in Chupan, re-set, pumping and monitoring disk tray must be based on inventory management training program, so that must count on the inventory program, the whole process of inventory methods, inventory forms, etc. used to fully understand; and to re-set cargo tray prison staff to identify training because recovery disk and disk monitoring personnel are not familiar with most of the goods, should strengthen the recovery disk and disk monitoring personnel to identify the goods, which will help inventory work.

3, to achieve operating procedures, improve the efficiency of storage operations

Ensure that all work storage of goods before prepared, cargo warehousing operation process standardized and effective, comprehensive inspection of goods, the right way, the documents fill in the correct specification, clear division of labor personnel departments collaboration is good, warehousing inspection process abnormalities deal with the problem properly in place, such as incomplete documentation, just does not match the quality is different, the number does not match, there is no single cargo, handling issues such as the wrong test. Thus, well-organized, reasonable arrangements, as far as possible at a reasonable cost of logistics to ensure that the library of goods according to quality, quantity, timely and safely to the customer, to ensure the operation efficient, accurate, low cost, and orderly.

4 warehousing operations information, improve the efficiency of warehousing operations

With the development of enterprises, enterprises need to invest in all aspects, especially in warehousing need to increase investment in terms of storage space, storage facilities, handling equipment, sorting equipment, bar code technology. Application of bar code technology can effectively solve the low efficiency of business operations, inventory control difficult, cargo difficult management problems, and could easily respond to market changes and unpredictable. Implement warehouse management information, it must establish a unique code for each product for each species, and the use of bar code printers to produce bar code label on the packaging or clothing hanging sign hanging in the product. This will not happen again can not find the goods, missed sales opportunity situation.

In short, the general business from Slotting Optimization, multi-level inventory, standardized operating procedures, warehousing and other aspects of information technology to improve the operating efficiency of the warehouse.